----------

|

Curio's - AKG's "Brass"CK12 capsule |

|

|

A quick look at it's history |

|

|

The "Brass" CK12, must surely rank as one of the most famous capsules ever designed. |

|

|

First used in the legendary AKG C12 valve microphone, and then in the C12a/b valve (Nuvistor) microphones that followed. |

|

|

Not forgetting it's deployment in the the excellent Telefunken (Elam) M250 and M251 series of valve microphones. |

|

|

Of course, the "Brass" CK12 capsule was also found in AKG's "Large Capsule" FET microphones i.e. C412, C414 and early examples of the C414EB and C414E1. |

|

|

The "Brass" CK12 capsule, was finally replaced by the original "Teflon" version of the CK12. Being very much cheaper to produce, but never sounding anything like the original "Brass" CK12 that it replaced. |

|

|

AKG went on to design and manufacture another capsule, in an attempt to "Emulate" the qualities of the original "Brass" CK12 capsule. This capsule being used in the C414TLII and the C12VR microphones. |

|

|

The original "Brass" CK12 capsule |

|

| What makes the "Brass" CK12 so special ? | |

| Those "Magical" qualities of the "Brass" CK12 capsule ..... maybe it's just down to the excellent design and manufacture of this "Precision" component. The "Brass" CK12 capsule is probably the most complex of any microphone capsule ever manufactured. | |

| If we take a closer look at the design and assembly of the "Brass" CK12, then maybe we can begin to appreciate why it sounds so good ! | |

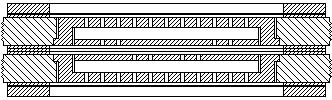

| Sectional views of "Brass" CK12 capsule | |

| Note - For reasons of clarity, fixing screws, together with their locating holes, are not shown. | |

|

Let us start by looking at "The Parts", that are utilized in the capsule assembly. |

|

|

Diaphragm Mounting Ring and Diaphragm |

|

|

Diaphragm to Backplate, Insulated Spacing Ring |

|

|

Insulated, Backplate, Mounting Ring |

|

|

Primary Backplate |

|

|

Secondary Backplate |

|

|

Note - The Secondary Backplate is engineered differently, on the front and rear capsule sections, see later |

|

|

When the above parts are fitted together, we have one half of the capsule assembly. Two assemblies, front and rear, are required to form the complete capsule. |

|

|

Front half of capsule |

|

|

Backplate to Backplate, Insulated Spacing Rings |

|

|

Rear half of capsule |

|

|

Finally, the front and rear halves of the capsule are assembled, together with the associate spacing rings, thus forming an "Critically Tuned" air-tight unit. |

|

|

The finished "Brass" CK12 capsule assembly |

|

| Let us now dismantle the "Brass" CK12 Capsule, and see what we find ! | |

|

Initially we have the complete capsule assembly, removed from the associated microphone |

|

|

Once the capsule supporting bracket and wiring connector tags have all been removed, we are left with just the capsule. Firstly we need to loosen the 3 screws that hold the two halves of the capsule assembly together. These are located on one face of the capsule only. The two halves of the capsule are now held together by a Locktite type of adhesive, used during manufacture. |

|

| Next, the 24 diaphragm retaining screws, 12 on each face of the capsule, need to be very carefully loosened, ready to be removed. The diaphragm mounting ring, together with the diaphragm, can now be removed. Along with the very thin insulated "Spacing Rings", that are used to determine the exact distance between rear of the "Diaphragm" and "Backplate". | |

| These "Spacing Rings" effecting the sensitivity of the capsule e.g. thinner the ring, the greater the sensitivity. The rings also having an influence on the frequency response and polar pattern of the final assembled capsule. | |

| The "Backplate Assembly", with the two halves of the capsule still intact, can now be separated for closer inspection.. Not forgetting to remove the very thin insulated "Spacing Rings", used to keep the two halves of the capsule assembly, the correct distance apart. These spacing rings are different from those used for determining the gap between the diaphragm to the backplate. | |

| These "Spacing Rings" effecting the frequency response and polar pattern of the assembled capsule. | |

| The backplate, have a very fine pitch screw thread around the circumference , and is screwed into the Perspex mounting ring. Again, this assembly is held firmly in place with a Locktie type of adhesive. At this stage of manufacture, the working face of the backplate assembly is now ready for final machining. There is, and has to be, a "Seamless" edge to the front face of the mounting ring and working surface of the backplate. The engineering tolerance's at this stage, are very tight indeed. | |

| To gain electrical access to the "Brass" backplate, a long fixing screw goes through the Perspex insulating ring and makes contact with the threaded hole, just visible, within the thread around the backplate. In the case of the C12 microphone, and other AKG models that use the "Brass" CK12 capsule, a coupling link is then used to electrically connect the two backplates together. In the case of the Telefunken 250/251 series, then the backplates of the "Brass" CK12 capsule, are not electrically connected together. | |

| If we take a closer look at the front and rear halves of the capsule, we can see that the holes in the rear of the backplates, are machined differently. This is all down to the design of the "Brass" CK12, and the required placement of the holes to obtain the desired frequency response and polar pattern of the capsule assembly. | |

| Indeed, the design of the each backplate is so intricate, that they are machined and assembled from two separate parts (I don't know of any other backplate assembly that is this complex). The holes in the front/working face, of the backplate, is the same for both halves of the capsule. However, the holes in the rear of the back plates are different, as mentioned in the last paragraph. The two parts of each backplate being screwed together (or dismantled) again via a very fine pitch screw thread on the circumference and inside edge of the backplate parts. The two components, that make up each backplate, are very fine examples of "Precision" engineering, and one of the reasons why it would be so expensive to re-create the "Brass" CK12 capsule today. Indeed the engineering requirements of any item that goes into making a capsule, require very high standards of precision and design detail. The "Brass" CK12 is a fine example of such craftsmanship. | |

| Note - Whilst dismantling the "Brass" CK12 capsule, for photographing, I made a note of the number of "Parts" used to make the capsule. There being no less than 55 items. | |